At present, more and more LED displays are entering the interior, especially for large hotels and shopping mall. So what are the requirements for large-scale hotels to use indoor full color LED screens?

In the indoor environment, the large-scale full color electronic led display with an area larger than 5sqm mainly has three options: ordinary rear projection, DLP (digital liquid crystal rear projection) and LED display.

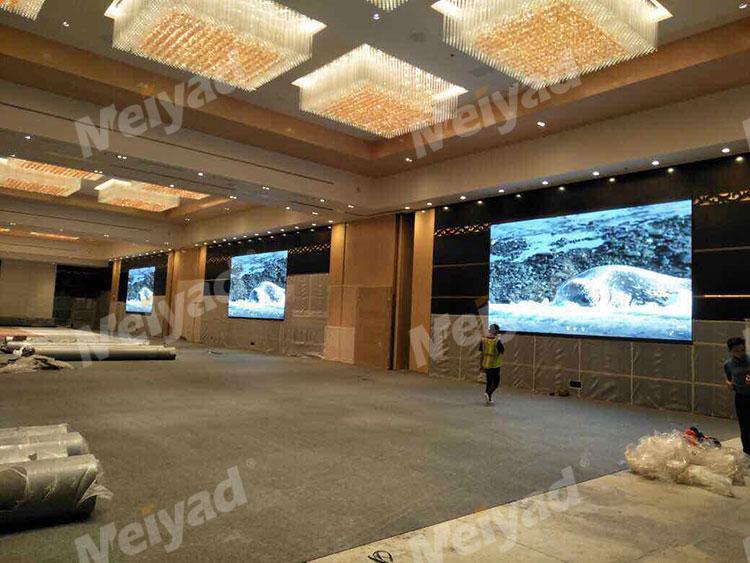

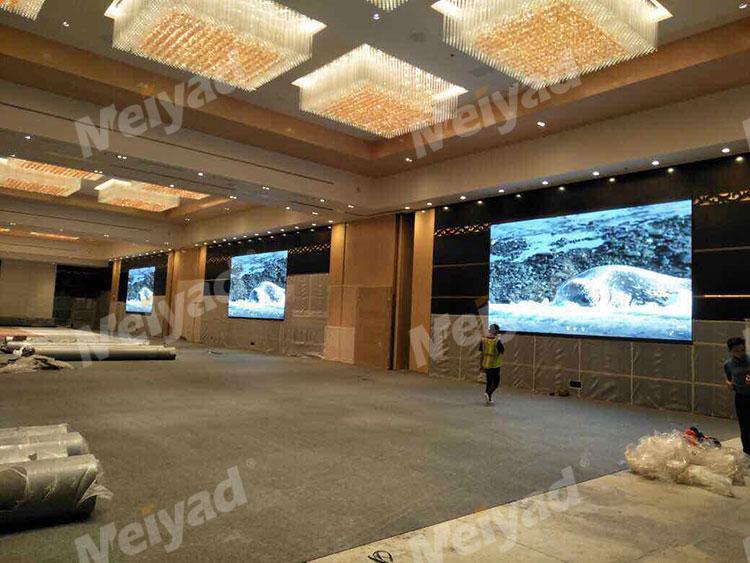

Meiyad Full Color Indoor LED Screen

The advantages of the rear projection type display screen are small pixel points and high definition, and the disadvantages are low brightness, small viewing angle, and short life of the lens lamp (only a few thousand hours). The advantage of plasma splicing is also that the pixel points are small and the definition is high. The disadvantage is that there are seams. At present, the smallest seam can reach 1mm. The rear projection and plasma display are suitable for closer viewing. The advantage of the LED display is that the brightness is high and there is no seaming. The disadvantage is that the pixel particles are thicker and the definition is lower. At present, the commercial indoor full color LED display has the highest density of P2, which is 250000 pixels/sqm. The LED display is suitable for indoor locations that viewing are far away.

Key issues to consider when selecting an indoor LED display.

When using the indoor LED display, it is mainly considered from the following aspects.

1) Real pixels and virtual pixels. Like the outdoor full color led screen, the pixels of the indoor full color led screen are also divided into real pixels and virtual pixels.

2) Chips. As with outdoor full color led screens, it is generally recommended that the indoor full color led screen blue and green tubes be made of Silan's chip, and the red tube with Opto or HUGA. High-end products are recommended to use Japanese Nichia and American CREE dies.

3) Package form. The LED surface of the indoor full color LED display has several types of single lamp, sub-surface sticker, three-ply-one-surface sticker and three-in-one surface sticker, and the appearance is also different. The advantages of surface-mount package are large viewing angle, good luminous consistency, and easy automatic welding processing. It is the mainstream product of full color LED screen, but the price is relatively high now. the single-lamp viewing angle is relatively small, the brightness is slightly higher, and the price is lower. The sub-surface sticker is actually a kind of single lamp. Single and sub-stickers are cheaper and are a transitional product.

4) Density. Since the indoor full color LED chip generates a large amount of heat and the density of the control circuit is high, the dot density of the commercially available full color led screen can be made high because a heat sink is needed to help the LED display to cool down. The current indoor led display screens mainly include P2.5, P3, P4, P5, P6, P7.62, P8, and P10.

5) Drive mode. The driving mode of the indoor full color LED display is constant current driving, which adopts dynamic scanning mode (mainly 1/4, 1/8, etc.). In the case of the same chip, the 1/4 scan circuit requires more, and the brightness is higher.